Never Do That Again

We say we never will, but what actions are we taking?

This article was published in the Fall 2023 LOGAINDUSTRY Magazine. Written by Peter Brecht on behalf of Darrick Huddleston.

Hydratongs and Pipe Stumps

On Aug 7th, 2023, with tripping operations underway, a member of the drill crew was caught between a moving hydratong and a pipe stump in the rotary. Thankfully, the floorhand sustained only minor injuries.

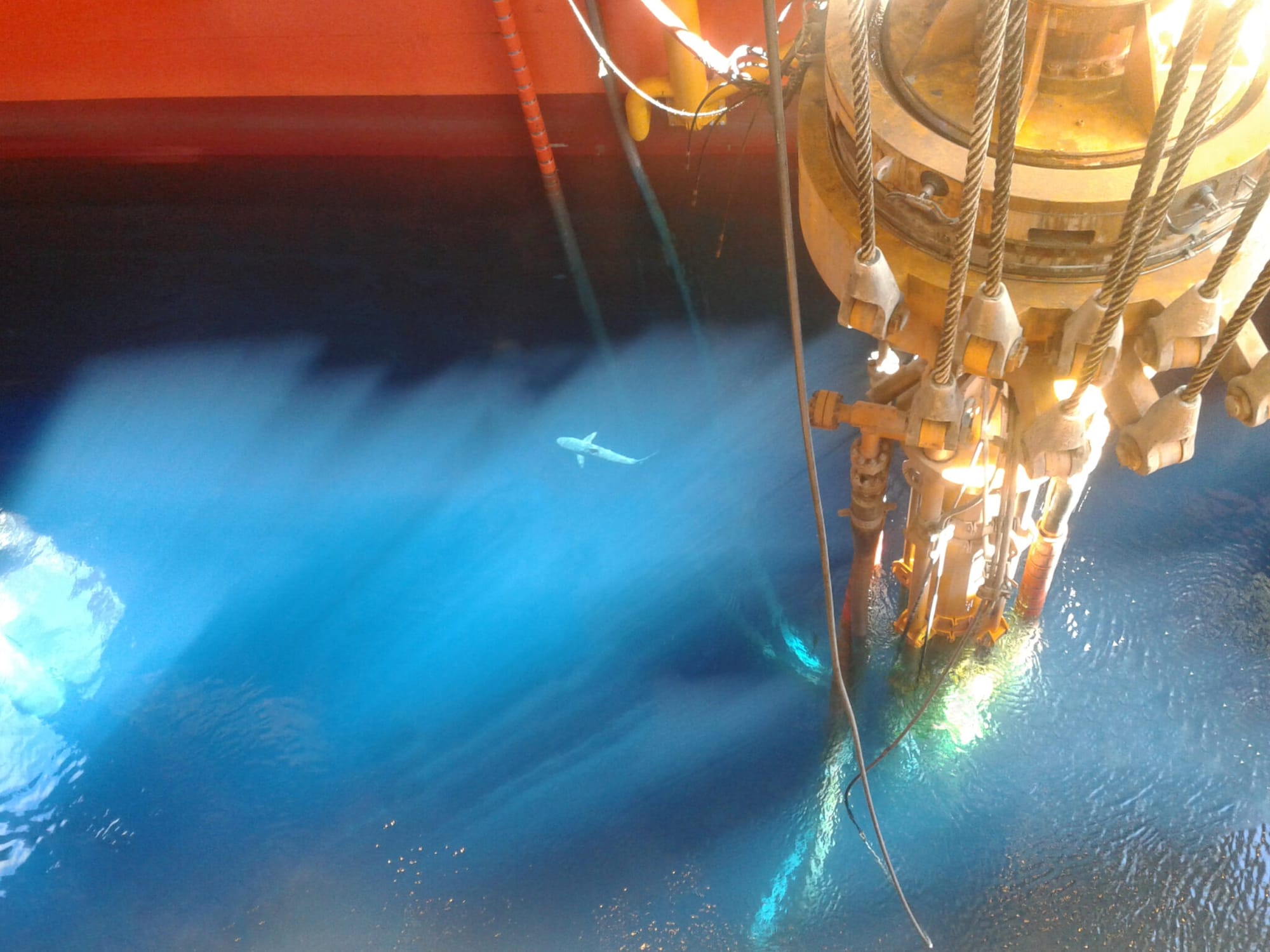

The drill floor is one of the most dangerous places to work on the rigs, and the illustration from the IADC Safety Alert 23-3 speaks for itself.

The oil and gas industry has come a long way in terms of safety, performance, and drilling capabilities. We’ve seen massive technological advancement since Kelly rigs and “warding off the woodpeckers from the derricks.”

One solution would be telling ourselves we’ll never do that again, but the follow through on that is almost impossible. So what’s next?

While the picture above clearly illustrates a hazardous situation, it also depicts a modern rig floor. It’s equipped with an electro-hydraulic automated pipe makeup and handling system, with combined digital and analogue cyberbase controls.

The driller and operator work from a positive pressure, intrinsically safe, and climate-controlled drill shack. Thousands of unique data points are monitored by the second in an ergonomically designed workspace. Automated emergency sequences are ready to be deployed with the press of a button.

It’s an astonishing feat of inventive and powerful engineering designed with the intent to reduce the need for personnel on the rig floor. In addition, it increases the productivity of drilling operations. While fully autonomous vehicles are being debated, a fully autonomous rig floor is not far from reality.

Engineering First

My 15 years of engineering experience on offshore and deepwater drilling rigs exposed me to numerous accidents and close calls. It’s also allowed me to experience the rapid progression of our industry in developing the safety culture of their workforce.

What were once commonplace accidents are now viewed as intolerable events.

At Falcon West Energy, my team works with oil and gas operators and provides feedback on insurance policies beginning with an engineering perspective. Risk assessment is comprehensive at every level in the field, and we uphold that same standard at our insurance brokerage.

Industry Advancements

Increased safety drives meaningful incentives across the entire operation, from increasing the number of contracts won to leveraging lower insurance expenses. Ultimately, drilling contracts are won with a combination of performance and safety records.

Engineering and technology provide avenues to manage safety risks, with a hierarchy of solutions. The best eliminate risks while others separate employees from direct exposure.

For example, a leading offshore drilling contractor has been developing AI and LiDAR technologies on drilling rigs, which halts hydraulic equipment should an employee enter the drill floor red zone. Another drilling contractor has been experimenting with a fully robotic arm to install riser bolts.

Here are just a few more of the phenomenal advancements we’ve made as an industry:

- Manual pipe tongs > NOV’s Iron roughneck

- Derrick hand required to rack back pipe > Pneumatic fingerboards and a PRS

- Driller on the drawworks brake on the floor > Cyberbase drilling controls

These new technologies will undoubtedly enhance drilling contractors’ positions in securing lucrative contracts with major operators.

The oil and gas industry has been around since 1858. We continue to build and drill, despite booms and busts, fierce competition, and close calls. Through it all, our safety practices have improved.

Increasing Impact

Make sure your insurance policies keep up with your company’s rate of safety innovation by reviewing these three areas:

- Clearly communicate all your safety technology with your stakeholders. This is valuable information for your insurance broker when negotiating insurance costs with underwriters each year.

- Don’t overlook any of your insurance carrier benefits. Your well control policy may cover costs of IADC or IWCF well control training for your employees because it reduces overall risk.

- Schedule all property and equipment, especially during periods of company growth. Ensuring accuracy means no risks are missed during reviews.

These three items come up during our policy reviews, and they often take some digging. However, each answer can increase the impact of your company’s overall strategy.